Understanding Cable Stranding Machines: The Backbone of Electrical Manufacturing

Release time:

2025-05-16

In the realm of electrical engineering, cable stranding machines are essential tools utilized in the manufacturing of various types of cables. These machines facilitate the process of twisting multiple wires together to form a single cohesive strand, which enhances the cable's overall performance, durability, and reliability. Understanding how these machines work and their significance in the prod

In the realm of electrical engineering, cable stranding machines are essential tools utilized in the manufacturing of various types of cables. These machines facilitate the process of twisting multiple wires together to form a single cohesive strand, which enhances the cable's overall performance, durability, and reliability. Understanding how these machines work and their significance in the production process can provide valuable insights for professionals in the industry.

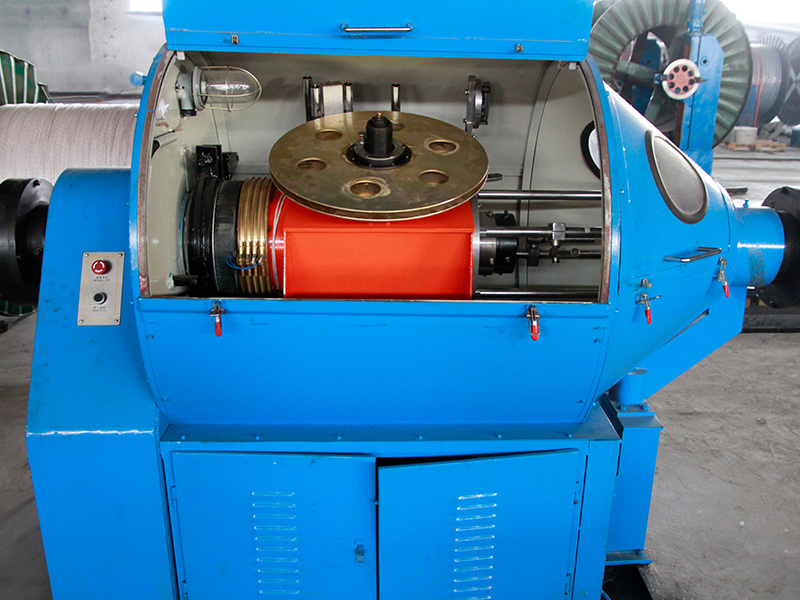

At its core, a cable stranding machine operates on the principle of arranging wires in a specific pattern, often referred to as stranding. The stranding process is critical because it not only improves the electrical properties of the cable but also increases its flexibility and resistance to external factors such as moisture and temperature fluctuations. The machine typically consists of a series of spools that hold the individual wires, which are then twisted together using a rotating mechanism designed to ensure even tension and alignment.

One of the key advantages of using a cable stranding machine is the increased efficiency it brings to the manufacturing process. By automating the stranding operation, manufacturers can produce large quantities of high-quality cable strands in a shorter amount of time. This efficiency translates to lower production costs and the ability to meet market demands more effectively.

Additionally, modern cable stranding machines come equipped with advanced technology that enhances their functionality. Features such as computerized controls, precision tensioning systems, and real-time monitoring ensure that the stranding process remains consistent and adheres to stringent quality standards. This technological integration minimizes human error and allows for greater customization of the cable strands to suit specific application requirements.

Cable stranding machines are versatile and can be employed in the production of various cable types, including power cables, communication cables, and specialty cables used in industries such as automotive and aerospace. Each application may require different stranding techniques and wire configurations, showcasing the adaptability of these machines in meeting diverse manufacturing needs.

Moreover, as the demand for high-performance cables continues to rise with advancements in technology, the importance of cable stranding machines in electrical manufacturing is only set to increase. Professionals in the field must stay informed about the latest developments in stranding technology and best practices to ensure optimal production outcomes.

In conclusion, cable stranding machines are pivotal in the electrical manufacturing industry, providing essential functions that enhance the quality and performance of electrical cables. By understanding the intricacies of these machines, professionals can leverage their capabilities to drive innovation and efficiency in cable production.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province