How a Drum Stranding Machine Enhances Wire Production Efficiency

Release time:

2025-05-15

The drum stranding machine is a cornerstone technology in the field of wire production, offering unparalleled efficiency, quality, and versatility

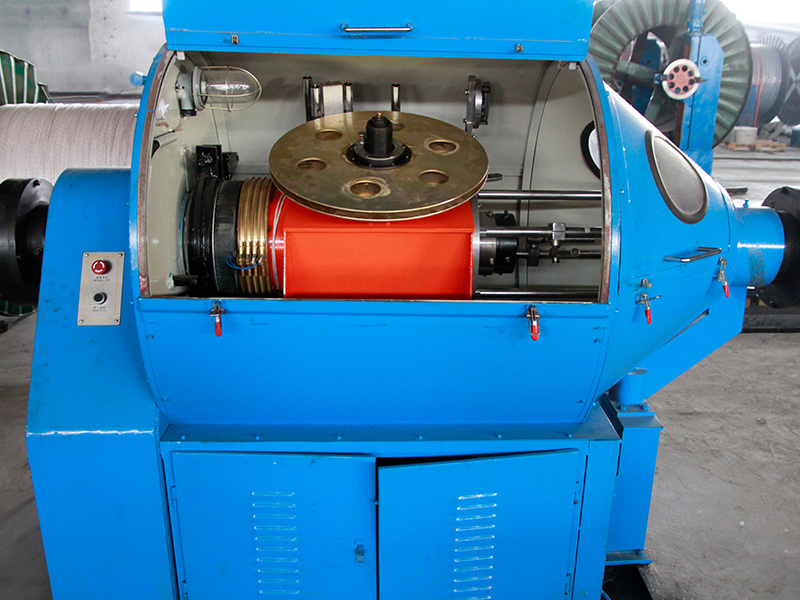

A drum stranding machine is an advanced piece of equipment designed specifically for the production of stranded wire. By twisting multiple strands of wire together, it creates a composite product that is both flexible and robust. This machine plays a vital role in producing various types of cables used in electrical wiring, telecommunications, and other applications.

The Mechanism Behind Drum Stranding

The operation of a drum stranding machine revolves around a series of rotating drums that facilitate the twisting and layering of wire strands. The process typically involves the following steps:

- Feeding of Wire Strands: The machine begins by feeding individual wire strands into the system. These strands are often made of copper or aluminum, known for their excellent conductivity.

- Twisting Process: As the drums rotate, they twist the strands together in a predetermined configuration. This twisting can be adjusted depending on the desired outcome, such as the number of strands and the degree of twist.

- Winding onto Spools: The final product, once twisted and formed, is wound onto spools, ready for further processing or distribution.

Different Types of Drum Stranding Machines

There is a variety of drum stranding machines available in the market, each designed for specific production needs:

- Single Twist Machines: Ideal for producing simple stranded wires, these machines twist wires at a single point, creating a basic stranded configuration.

- Double Twist Machines: These machines provide greater flexibility by allowing for more complex stranding patterns, making them suitable for a wider range of applications.

- Automatic Drum Stranding Machines: Equipped with advanced controls and automation features, these machines enhance productivity by minimizing the need for manual intervention.

Advantages of Using a Drum Stranding Machine

The implementation of a drum stranding machine in wire production offers numerous advantages, significantly impacting efficiency and output quality. Here are some of the primary benefits:

1. Increased Production Speed

One of the most significant advantages of drum stranding machines is their speed. These machines can operate at high speeds without compromising the quality of the stranded wire. This efficiency leads to increased overall production output, allowing manufacturers to meet high demand with ease.

2. Improved Product Quality

Drum stranding machines ensure consistent twisting and layering of wire strands, resulting in high-quality products. The precision involved in the operation minimizes defects, such as uneven twisting or inconsistent tension, leading to a more reliable end product.

3. Versatility and Customization

With the ability to adjust the twisting patterns and strand configurations, drum stranding machines offer manufacturers the flexibility to produce a wide variety of wire types. This adaptability is crucial for meeting diverse customer needs and industry standards.

4. Reduced Labor Costs

The automation capabilities of modern drum stranding machines significantly reduce the need for manual labor. By streamlining the production process, manufacturers can cut down on labor costs while reallocating their workforce to more strategic roles within the company.

5. Enhanced Safety Features

Safety is a paramount concern in any manufacturing environment. Drum stranding machines are typically equipped with advanced safety features, such as emergency stop buttons and protective enclosures, ensuring a safer working environment for operators.

The Role of Technology in Drum Stranding Machines

The evolution of technology has led to the development of highly sophisticated drum stranding machines that incorporate several advanced features:

1. Automated Control Systems

Modern drum stranding machines often feature automated control systems that allow for real-time monitoring and adjustments. This level of control ensures that production parameters remain consistent, enhancing overall efficiency.

2. Data Analytics

Some advanced machines come equipped with data analytics capabilities that track production metrics. This data can be invaluable for identifying bottlenecks and areas for improvement, allowing manufacturers to optimize their processes continuously.

3. Remote Monitoring Capabilities

With the rise of Industry 4.0, many drum stranding machines now offer remote monitoring capabilities. This allows operators and management to oversee production processes from anywhere, ensuring that any issues can be addressed promptly.

Common Applications of Drum Stranding Machines

Drum stranding machines are utilized across various industries, demonstrating their versatility and importance:

1. Electrical Cable Manufacturing

The most prevalent application of drum stranding machines is in the production of electrical cables. These machines create the stranded wires that form the backbone of electrical systems, providing reliable conductivity.

2. Telecommunications

In the telecommunications sector, drum stranding machines are used to manufacture cables for data transmission. The quality and efficiency of these cables are crucial for maintaining high-speed internet and communication systems.

3. Automotive Industry

As the automotive industry continues to evolve, so does its demand for advanced wiring solutions. Drum stranding machines play a vital role in manufacturing the complex wiring harnesses found in modern vehicles.

Challenges Faced in Drum Stranding Machine Operation

Despite the numerous advantages, manufacturers may face challenges when operating drum stranding machines:

1. Maintenance Requirements

Like any machinery, drum stranding machines require regular maintenance to function optimally. Neglecting maintenance can lead to reduced efficiency and potential breakdowns.

2. Initial Investment Costs

The initial investment for a high-quality drum stranding machine can be substantial. However, considering the long-term efficiency gains, many manufacturers find that the investment pays off over time.

3. Skill Requirements

While automation has reduced the need for manual labor, skilled technicians are still required to operate and maintain drum stranding machines effectively. Training staff to handle these advanced machines is essential for maximizing their potential.

Conclusion

The drum stranding machine is a cornerstone technology in the field of wire production, offering unparalleled efficiency, quality, and versatility. By understanding its operational mechanisms and the benefits it brings to electrical and electronic manufacturing, businesses can leverage this technology to enhance their production processes. As the industry continues to evolve, investing in advanced stranding technologies will be crucial for manufacturers looking to maintain a competitive edge.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province