Understanding Steel Wire Armouring Machines: Essential Insights for the Electrical Industry

Release time:

2025-02-19

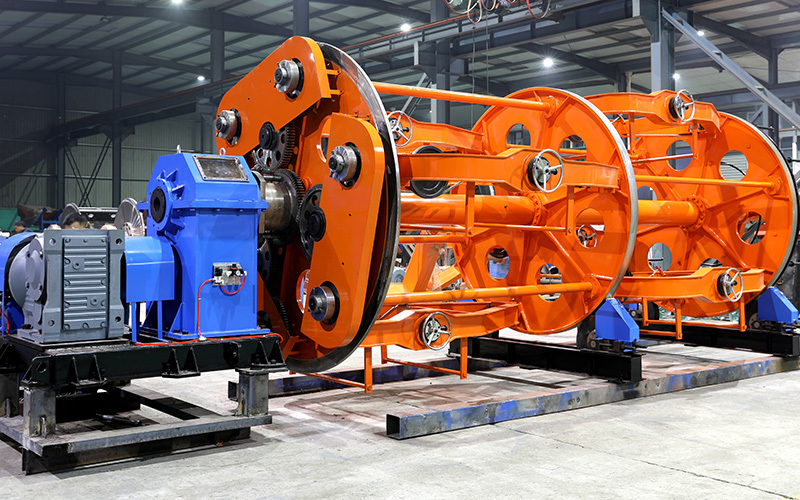

Steel Wire Armouring machines are indispensable in the electrical manufacturing industry, providing essential reinforcement for cables that are exposed to various challenges

Steel Wire Armouring machines play a pivotal role in the production of electrical cables, particularly in reinforcing them against mechanical stress and enhancing their durability. The process of armoring involves wrapping steel wires around the core of the cable, providing a protective layer that can withstand harsh environmental conditions, physical impacts, and abrasion. This feature is especially crucial for cables used in industrial applications, underground installations, and areas susceptible to external damage.

The operation of a Steel Wire Armouring machine is characterized by several key processes. Initially, the base cable is fed into the machine, where it is precisely aligned for optimal wire application. The machine then automatically wraps the steel wires around the cable at specified intervals, ensuring consistent tension and coverage. Advanced machines incorporate sophisticated technology that allows for real-time monitoring and adjustments, which significantly enhances the quality of the final product.

One of the primary advantages of using Steel Wire Armouring machines is increased production efficiency. Automation in the armouring process reduces manual labor and minimizes human error, leading to faster production cycles. Additionally, these machines are designed to accommodate various cable sizes and wire diameters, making them versatile tools for manufacturers. This flexibility is vital for companies that produce a wide range of electrical cables tailored to different applications.

Furthermore, the use of Steel Wire Armouring enhances the reliability of electrical cables. Cables that are armoured with steel wire are less likely to suffer damage from environmental factors, such as moisture, temperature fluctuations, or physical impact. This reliability translates to lower maintenance costs and longer service life for the cables, ultimately benefiting both manufacturers and end-users.

In terms of safety, Steel Wire Armouring machines contribute to the overall safety of electrical installations. The robust nature of armoured cables helps prevent accidental damage during installation or operation, which is crucial in high-stakes environments such as construction sites, factories, and utilities. Since these cables are designed to meet stringent safety standards, their use can significantly mitigate risks associated with electrical failures.

Steel Wire Armouring machines are indispensable in the electrical manufacturing industry, providing essential reinforcement for cables that are exposed to various challenges. Their efficiency, flexibility, and contribution to safety make them a critical investment for manufacturers aiming to deliver high-quality electrical products. As technology continues to advance, the capabilities and features of Steel Wire Armouring machines are expected to evolve, further enhancing their role in the industry.

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province