Understanding the Benefits of Using a Drum Stranding Machine in Electrical Manufacturing

Release time:

2025-02-04

Understanding the Benefits of Using a Drum Stranding Machine in Electrical Manufacturing Table of Contents Introduction to Drum Stranding Machines What is a Drum Stranding Machine? Importance of Drum Stranding Machines in Electrical Manufacturing Key Benefits of Using a Drum Stranding Machine Enhanced Efficiency in Production Improved Quality Contr

Understanding the Benefits of Using a Drum Stranding Machine in Electrical Manufacturing

Table of Contents

- Introduction to Drum Stranding Machines

- What is a Drum Stranding Machine?

- Importance of Drum Stranding Machines in Electrical Manufacturing

- Key Benefits of Using a Drum Stranding Machine

- Enhanced Efficiency in Production

- Improved Quality Control

- Cost-Effectiveness and Resource Management

- Versatility in Electrical Applications

- How to Choose the Right Drum Stranding Machine

- Maintenance Tips for Drum Stranding Machines

- Future Trends in Drum Stranding Technology

- Conclusion

- Frequently Asked Questions

Introduction to Drum Stranding Machines

In the fast-paced world of electrical manufacturing, efficiency and quality are paramount. Companies are constantly seeking ways to streamline processes and enhance their product offerings. One of the most innovative solutions that have emerged in recent years is the **drum stranding machine**. This specialized equipment plays a vital role in the production of various **electrical components**, ensuring optimal performance and reliability.

What is a Drum Stranding Machine?

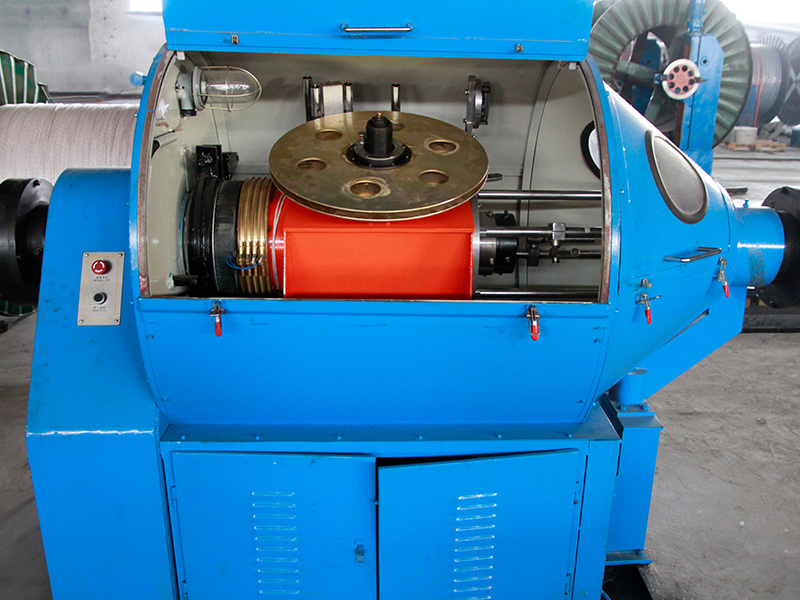

A **drum stranding machine** is a sophisticated piece of equipment designed to twist together multiple strands of wire or fiber to create a composite cable. Typically, these machines feature a rotating drum, which holds the wires and facilitates the stranding process, ensuring uniform tension and alignment.

Drum stranding machines are used in a variety of applications, including the manufacture of **electric cables**, **optical fibers**, and other electrical components. Their ability to handle different materials and configurations makes them an essential tool in modern manufacturing.

Importance of Drum Stranding Machines in Electrical Manufacturing

As technology continues to advance, the demand for high-quality electrical components has surged. **Drum stranding machines** provide manufacturers with a competitive edge by ensuring that their products meet stringent performance standards. These machines are integral to the manufacturing process, allowing companies to produce cables and wires that are not only reliable but also capable of meeting diverse customer needs.

The transition from traditional stranding methods to drum-based systems has proven to be a game-changer in terms of efficiency, accuracy, and adaptability. As manufacturers embrace these innovations, the industry as a whole stands to benefit from improved manufacturing practices.

Key Benefits of Using a Drum Stranding Machine

Drum stranding machines offer numerous advantages that can significantly enhance the production capabilities of electrical manufacturers. Here are some of the key benefits:

Enhanced Efficiency in Production

One of the primary benefits of using a drum stranding machine is the **enhanced efficiency** it brings to the production line. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of cable in a shorter amount of time.

Additionally, the automated processes involved in drum stranding reduce the need for manual labor, minimizing human error and increasing throughput. This efficiency translates to faster delivery times and the ability to meet increasing demand without compromising on quality.

Improved Quality Control

Quality control is paramount in electrical manufacturing, as any defects can lead to product failures and safety hazards. Drum stranding machines enhance quality control through precise engineering and consistent manufacturing processes.

These machines are equipped with advanced monitoring systems that track the tension and alignment of the strands during production. This real-time data allows manufacturers to identify and rectify potential issues before they escalate, resulting in superior products with fewer defects.

Cost-Effectiveness and Resource Management

Investing in a drum stranding machine can lead to significant cost savings for manufacturers. The increased efficiency and reduced labor costs associated with these machines allow companies to allocate resources more effectively.

Moreover, the precision of drum stranding minimizes material waste, further driving down production costs. By enhancing **resource management**, manufacturers can improve their bottom line and reinvest savings into innovation and growth.

Versatility in Electrical Applications

One of the standout features of drum stranding machines is their **versatility**. These machines can handle a wide range of materials, including copper, aluminum, and fiber optics, making them suitable for various applications in the electrical manufacturing sector.

Whether it’s producing power cables, telecommunications cables, or specialized electronic components, drum stranding machines can be customized to meet specific production requirements. This adaptability allows manufacturers to respond to market changes and customer demands quickly.

How to Choose the Right Drum Stranding Machine

Selecting the right drum stranding machine is crucial for maximizing production efficiency and quality. Here are some factors to consider:

1. **Material Compatibility**: Ensure the machine can handle the materials you plan to use, whether they are metallic wires or optical fibers.

2. **Production Capacity**: Consider your production volume and choose a machine that can meet your output needs without strain.

3. **Technology and Features**: Look for machines equipped with advanced monitoring and control systems that enhance quality and efficiency.

4. **Space and Layout**: Assess the available space in your facility and choose a machine that fits well within your production line layout.

5. **Supplier Reputation**: Research suppliers and manufacturers to ensure you’re investing in a reliable and reputable machine that comes with good support and service.

Maintenance Tips for Drum Stranding Machines

To maintain the longevity and performance of your drum stranding machine, regular maintenance is essential. Here are some key maintenance tips:

1. **Regular Inspections**: Conduct routine inspections to identify any wear and tear on components, ensuring timely repairs.

2. **Lubrication**: Keep moving parts well-lubricated to minimize friction and prevent overheating.

3. **Cleaning**: Maintain a clean work environment around the machine to reduce the risk of dust and debris affecting operation.

4. **Calibration**: Regularly calibrate the machine to ensure accurate stranding and alignment.

5. **Training**: Provide adequate training for operators to ensure they are familiar with the machine’s functions and maintenance requirements.

Future Trends in Drum Stranding Technology

The future of drum stranding technology looks promising with advancements in automation, artificial intelligence, and materials science. Manufacturers are increasingly incorporating smart technologies into their equipment, allowing for enhanced monitoring, predictive maintenance, and process optimization.

Additionally, as the demand for renewable energy and electric vehicles grows, drum stranding machines will likely evolve to accommodate new materials and designs. Staying abreast of these trends will be essential for manufacturers aiming to maintain a competitive edge in the evolving electrical landscape.

Conclusion

In conclusion, drum stranding machines represent a significant advancement in the field of electrical manufacturing. Their ability to enhance efficiency, improve quality, and reduce costs makes them indispensable tools for modern manufacturers. By selecting the right machine and implementing best practices in maintenance, companies can ensure their production processes remain competitive and responsive to customer demands. As technology continues to evolve, embracing innovations in drum stranding will undoubtedly play a crucial role in shaping the future of electrical manufacturing.

Frequently Asked Questions

1. What types of cables can be produced using a drum stranding machine?

Drum stranding machines can produce a variety of cables, including power cables, telecommunications cables, and specialized electronic components. They are suitable for both metallic and fiber optic materials.

2. How fast can a drum stranding machine operate?

The speed of a drum stranding machine varies based on the model and materials used, but many machines can operate at high speeds, producing significant quantities of cable in a short time frame.

3. What are the key components of a drum stranding machine?

Key components include the rotating drum, tension control systems, monitoring equipment, and stranding heads. Each component plays a vital role in ensuring efficient and accurate stranding.

4. How often should maintenance be performed on a drum stranding machine?

Maintenance should be performed regularly, with routine inspections scheduled monthly or quarterly, depending on usage. Additionally, daily checks may be necessary to ensure optimal operation.

5. Can drum stranding machines be customized for specific needs?

Yes, drum stranding machines can often be customized to meet specific production requirements, including adjustments for material types and production volume.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province